How To Replace or Repair Cast Iron Pipe Without Excavation!

Got Broken Sewer Cast Iron Under Slab or Roots In Drain Causing Backups?

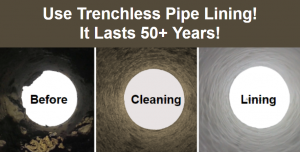

This 50-year warranty pipe lining technology stops backups permanently

The Problem – Repeated Backups!

Homes built before 1972 all have cast iron sewer pipes. Over time, most of the corrosion occurs along the bottom which creates a wide crack. The serrated edges of the crack catch on debris, which causes repeated backups. Plumbers want to excavate your floors to replace these pipes, typically costing $50,000 for a 2,000-square-foot house!

The Solution

Since 2004, we have been relining the inside of these pipes with patented pipe restoration technology, which typically takes 3-4 days, costs 60% less than excavation, and tenants can stay home and use the plumbing 20 hours per day! We save about 400 homes per year, plus many high-rise buildings, restaurants, etc. We make final video recordings of the pipes when done. It comes with a has a 50-year warranty that is transferable to new homeowners!

How Is This 50-Year Warranty Pipe Lining Installed?

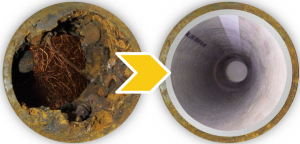

From outside your property, we open the cast iron pipe that needs to be repaired, clean out the rust, scale, and roots, and then install a new “pipe liner” or sleeve that has been saturated with a special self-hardening epoxy resin. The liner contains a balloon that is inflated for 3 hours while the resin becomes rock-hard. Then the balloon is removed and a video inspection is performed to ensure correct installation. The pipe is put back into use within 1 day. Learn more pipe lining installation details here.

Video Of Re-Lined (Repaired) Cast Iron Drain Pipe

Benefits Of Trenchless Pipe Lining (a.k.a. Cured In Place Pipe, CIPP)

- No Excavation Required – no permitting and no inspections required

- Less expensive – pipe relining costs about 70% less than excavation

- Save Your Floor Tile/Marble/Wood – it’s usually impossible to find matching floor surfaces that were installed decades ago

- Clean, No sewer bacteria in your home – since the drain is not being cut into pieces inside your residence, there is no need to sanitize the property afterwards

- Stay in your residence – pipe relining is done from outside, so you can stay in your residence

- Speed – pipe lining takes 1 day, not 3 weeks as for pipe replacement by excavation

- Environmentally friendly – pipe replacement by excavation means tons of waste concrete and pipe have to be disposed of in landfills

Must Watch! The 2 Common Technologies Used As Of 2023

How Much Does Trenchless Cast Iron Pipe Replacement Cost?

For residential purposes, from $150-$200 per linear foot of lining. It varies by pipe diameter, installation complexity, and customer attitude. For Commercial purposes, $175-$225 per linear foot. Commercial installation would be high-rise buildings, factories, shopping malls etc. These installations are more complex since pipe downtime, even for just 4 hours, usually has an enormous impact on tenants and can cause much economic impact for any loss of use of pipe. Note also, every trenchless pipe lining company will have a minimum charge in order to mobilize their expensive equipment and trained crew.

How Strong Is The Pipe Lining?

The pipe liner is a fabric tube made of polyester which is then “wet out” with a 2-part epoxy resin which is mixed together in a certain proportion. In about 30 minutes resin heats up by itself to 180 degrees Fahrenheit due to an exothermic chemical reaction and becomes rock hard.

The resulting new inner pipe liner is so strong that it is a stand-alone pipe, not needing the old exterior pipe for structural integrity. The liner is designed to go under load bearing footers, roads, driveways etc.