West Palm Beach Trenchless Pipe Lining Company Installs New Sewer Drains Without Excavation!

“Trenchless Pipe Lining” Costs 60% Less Than Digging

For a 2,000 sq. ft. house in Palm Beach County:

Trenchless Pipe Lining

-

- Takes 4 days

- Costs $17,000

- Has a 50-year warranty!

- Stay in home

Pipe Excavation & Replacement

-

- Takes 4-8 weeks

- Costs $50,000 – $75,000

- Tile, Terrazzo, Marble, Wood replacement

- Kitchen and bathroom cabinets replacement

- Must vacate home

Our Pipe Lining Has A 50-Year Warranty!

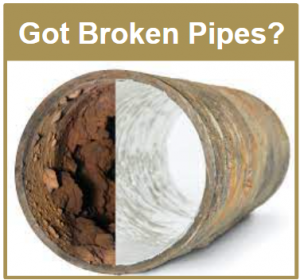

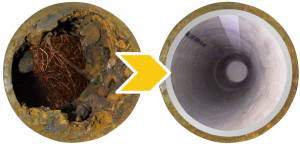

All homes in West Palm Beach built before 1972, have cast iron drain pipes under the slab. Over time, the bottom of the pipe corrodes and becomes so thin that a crack forms that has serrated edges. That causes toilet paper and other debris to get stuck, which in turn causes repeated backups into toilets, showers, and bathtubs.

To replace these cast iron pipes the old-fashioned way by excavation methods, typically takes 4 to 8 weeks, destroys all the floor surfaces, and the kitchen and bathroom cabinets, and costs $50,000 to $75,000.

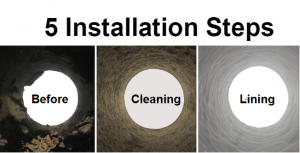

On the other hand, our trenchless pipelining technologies can restore those pipes within three to 4 days without any digging, and only costs about $17,000 for the typical 2000-square-foot home, and comes with a 50-year warranty!

Here Are (1,000+ Voluntary) Names and Phone Numbers Of Your Neighbors Who Have Used Our Services Since 2004

Must Watch! The 2 Common Technologies Used As Of 2023

Recent Jobs In The West Palm Beach Area:

West Palm Beach: Janice 561-324-4610: installed 28’ main line, 10’ kitchen line, and 10’ laundry line

West Palm Beach: Jeff 561-687-1188: installed 300ft lateral

West Palm Beach: Micheal 561-598-0076: installed 37’ main line and 15ft laundry line

West Palm Beach: Tatyana 630-730-8111: Installed main and lateral

West Palm Beach: Tatyana 630-730-8111: Installed main line and lateral

West Palm Beach: Tina 561-324-4686: Installed main and lateral

Lake Worth: Bob 305-394-2449: Installed main, branches, and lateral

Lake Worth: Janice 561-827-7024: installed 26’ main line, 24’ kitchen line, and 20’ master bathroom line

Lake Worth: Matthew 561-490-9381: Installed main, branches, and lateral

North Palm Beach: Caroline 561-459-6454: installed main line and all branches

North Palm Beach: Colby 561-254-0807: installed 41’ main line, 40’ kitchen line, and 16’ laundry line

Delray Beach: Ken 917-670-4771: Installed main, branches, and lateral

Why Have So Few People Heard Of Trenchless Pipe Lining?

It is actually not a new technology! We have been using it since 1998 to restore around 600 homes per year in S. Florida.

Actually, the technology has been around for several decades, but it is possible that many people are still unfamiliar with it for various reasons. Here are some factors that may contribute to its lesser-known status:

- Limited marketing and awareness: Trenchless pipe lining may not have received as much marketing or media attention compared to other plumbing methods. As a result, the general public may not be as familiar with this technology.

- Regional variations: The adoption and popularity of trenchless pipe lining can vary across different regions and countries. It is possible that in certain areas, the awareness and use of this technology are not as widespread.

- Professional knowledge: Trenchless pipe lining requires specialized knowledge and training. The general public may not be aware of this method if they have not encountered plumbing issues that necessitate pipe repair or replacement. Most people will never need to replace their pipes in their lifetimes!

- Alternative names: Trenchless pipe lining is also referred to as CIPP lining, cured-in-place pipe, or trenchless sewer repair. The use of different terminology can contribute to confusion and limited awareness among the general population.

Trenchless pipe lining technology has been in use since the 1970s and has evolved over time. It was originally developed in the United Kingdom by Eric Wood and his team at the Thames Water Authority’s research facility. Since then, the technology has been refined and adopted in various countries around the world.

While trenchless pipe lining offers advantages such as reduced excavation, minimal disruption, and cost-effectiveness, its visibility and familiarity among the general public can still vary. However, within the plumbing industry, trenchless pipe lining is well-known and widely used as an alternative to traditional excavation methods.

Why Is Trenchless Pipe Lining So Popular In West Palm?

Trenchless pipe lining has gained popularity in old and expensive neighborhoods like West Palm Beach for several reasons:

- Minimized Disruption: Old neighborhoods often have mature trees, landscaping, and infrastructure that residents want to preserve. Trenchless pipe lining allows repairs and replacements to be done without extensive excavation, minimizing disruption to the environment and infrastructure. It eliminates the need for digging up lawns, driveways, sidewalks, and other valuable property features.

- Preserving Aesthetics: Expensive neighborhoods tend to have strict regulations and guidelines regarding the preservation of visual appeal. Trenchless pipe lining offers a non-destructive solution that doesn’t require digging up streets or creating unsightly trenches. This method enables repairs to be completed without compromising the aesthetic value of the neighborhood.

- Cost-Effectiveness: While trenchless pipe lining can initially seem more expensive than traditional methods, it often proves to be more cost-effective in the long run. In old neighborhoods with complex underground networks, traditional excavation and replacement methods can be labor-intensive and time-consuming. Trenchless pipe lining reduces labor and material costs associated with excavation, resulting in overall cost savings.

- Environmental Considerations: Trenchless pipe lining aligns well with growing environmental concerns. By avoiding extensive excavation, it reduces the carbon footprint associated with transportation, waste disposal, and the use of heavy machinery. In upscale neighborhoods like Palmetto Bay, where environmental consciousness may be high, trenchless pipe lining is seen as a greener and more sustainable choice.

Why Don’t More Regular Plumbers Offer This Technology?

- Limited expertise or equipment: Trenchless pipe lining requires specialized training and equipment. Some plumbers may not have the necessary knowledge or experience in this specific method of pipe repair or replacement. It requires investment in specialized tools and training, which may not be feasible for all plumbing companies.

- Cost considerations: Trenchless pipe lining can be a cost-effective solution in many cases, but the initial investment in equipment and training may be significant for plumbing companies. Some plumbers might be hesitant to invest in trenchless technology if they don’t anticipate sufficient demand or if they primarily serve areas with older infrastructure where trenchless methods are less applicable.

- Preference for traditional methods: Some plumbers may have a preference for traditional pipe repair and replacement methods that they are more familiar with and have used for years. They may prefer to stick to what they know rather than adopting newer trenchless technologies.