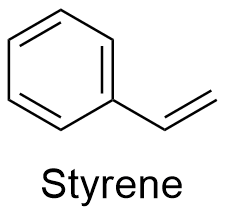

Styrenes are a class of chemicals known as styrene monomers. Styrene is a colorless liquid hydrocarbon derived from petroleum, and it belongs to a group of chemicals called aromatic compounds. It is primarily used in the production of plastics, synthetic rubber, and resins.

Styrenes are a class of chemicals known as styrene monomers. Styrene is a colorless liquid hydrocarbon derived from petroleum, and it belongs to a group of chemicals called aromatic compounds. It is primarily used in the production of plastics, synthetic rubber, and resins.

Are Styrenes Added To Pipe Lining Resins and Epoxies?

Styrene is used in trenchless pipe lining epoxies and resins because of its excellent polymerization properties. When styrene undergoes polymerization, it forms a hard, durable, and chemically resistant material known as polystyrene. Polystyrene is commonly used as a protective coating and lining material due to its high strength and resistance to corrosion.

In the context of trenchless pipe lining, styrene is often used as a reactive monomer in the formulation of epoxy resins. These resins are applied to the interior surface of existing pipes to create a new, seamless lining that reinforces and protects the pipe. When the epoxy resin is applied, styrene undergoes polymerization, transforming into a solid, inert material that adheres to the pipe surface.

Advantages Of Styrenes

The use of styrenes in trenchless pipe lining epoxies and resins offers several advantages. It provides excellent adhesion to the pipe surface, creating a strong bond that helps prevent leaks and cracks. Styrene-based resins also exhibit high chemical resistance, which makes them suitable for various environments, including sewer systems and industrial pipelines.

Health And Environmental Concerns

It’s worth noting that styrene has raised some environmental and health concerns due to its potential for release during the curing process and as a volatile organic compound (VOC). They are not environmentally friendly due to their persistence in the environment, contributing to long-term impacts on fish and wildlife.

Proper safety measures and ventilation should be employed during the application of styrene-containing products to mitigate any associated risks.