Pompano Beach Trenchless Sewer Relining Service Restores Cast Iron Pipes Under Slabs For 50+ Years, Without Excavation!

“Trenchless Pipe Lining” Costs 60% Less Than Digging

For a 2,000 sq. ft. house in Miami:

Trenchless Pipe Lining

- Takes 4 days

- Costs $17,000

- Has a 50-year warranty!

- Stay in home

Pipe Excavation & Replacement

- Takes 4-8 weeks

- Costs $50,000 – $75,000

- Tile, Terrazzo, Marble, Wood replacement

- Kitchen and bathroom cabinets replacement

- Must vacate home

Our Pipe Lining Has A 50-Year Warranty!

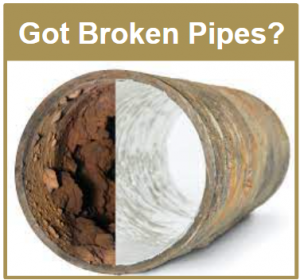

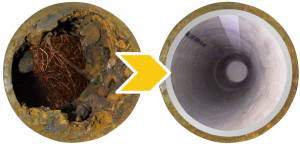

All homes in Broward County built before 1972, have cast iron drain pipes under the slab. Over time, the bottom of the pipe corrodes and becomes so thin that a crack forms that has serrated edges. That causes toilet paper and other debris to get stuck, which in turn causes repeated backups into toilets, showers, and bathtubs.

To replace these cast iron pipes the old-fashioned way by excavation methods, typically takes 4 to 8 weeks, destroys all the floor surfaces, and the kitchen and bathroom cabinets, and costs $50,000 to $75,000.

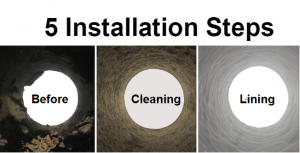

On the other hand, our trenchless pipelining technologies can restore those pipes within three to 4 days without any digging, and only costs about $17,000 for the typical 2000-square-foot home, and comes with a 50-year warranty!

Here Are (1,000+ Voluntary) Names and Phone Numbers Of Your Neighbors Who Have Used Our Services Since 2004

Must Watch! The 2 Common Technologies Used As Of 2023

Here are a few recent references in Pompano Beach:

| ● Pompano Beach: Bobby 605-484-0544: installed kitchen line |

| ● Pompano Beach: Carol 905-449-9060: installed 28′ main line and 32′ bathroom branch line as well as crumbled vertical cast iron stack replacement from roof down to horizontal section of re-installed pipe underground (excludes roof sealing around new stack that requires a licensed roofing contractor) |

| ● Pompano Beach: John 954-401-9150: installed 46’ of cast iron drain serving laundry, kitchen and 2 bathrooms |

| ● Pompano Beach: Stan 917-450-4210: installed 90′ main line |

| ● Pompano Beach: Trey 404-735-8698: 25′ from PVC wye, around 90 degree bend in floor, and then remaining 25′ |

| ● Pompano Beach: Victoria 954-816-7647: installed 45’ main line to rear bathroom |

Why Is Trenchless Pipe Lining So Popular In South Florida?

Trenchless pipe lining, also known as cured-in-place pipe (CIPP) lining, has gained popularity in old and expensive neighborhoods like Palmetto Bay for several reasons:

- Minimized Disruption: Old neighborhoods often have mature trees, landscaping, and infrastructure that residents want to preserve. Trenchless pipe lining allows repairs and replacements to be done without extensive excavation, minimizing disruption to the environment and infrastructure. It eliminates the need for digging up lawns, driveways, sidewalks, and other valuable property features.

- Preserving Aesthetics: Expensive neighborhoods tend to have strict regulations and guidelines regarding the preservation of visual appeal. Trenchless pipe lining offers a non-destructive solution that doesn’t require digging up streets or creating unsightly trenches. This method enables repairs to be completed without compromising the aesthetic value of the neighborhood.

- Cost-Effectiveness: While trenchless pipe lining can initially seem more expensive than traditional methods, it often proves to be more cost-effective in the long run. In old neighborhoods with complex underground networks, traditional excavation and replacement methods can be labor-intensive and time-consuming. Trenchless pipe lining reduces labor and material costs associated with excavation, resulting in overall cost savings.

- Durability and Longevity: Trenchless pipe lining involves installing a seamless, epoxy-saturated liner inside the existing pipe, creating a durable and long-lasting solution. This method can extend the lifespan of the pipes by several decades, reducing the need for frequent repairs and replacements. In old and expensive neighborhoods, where preserving infrastructure is crucial, trenchless pipe lining offers a reliable and sustainable solution.

- Minimal Displacement: Traditional pipe replacement methods often require residents to temporarily relocate or endure inconveniences like road closures. Trenchless pipe lining minimizes such displacements since the repairs can be done with minimal disruption to the residents’ daily lives. This aspect is particularly appealing in expensive neighborhoods, where residents may have higher expectations for comfort and convenience.

- Environmental Considerations: Trenchless pipe lining aligns well with growing environmental concerns. By avoiding extensive excavation, it reduces the carbon footprint associated with transportation, waste disposal, and the use of heavy machinery. In upscale neighborhoods like Palmetto Bay, where environmental consciousness may be high, trenchless pipe lining is seen as a greener and more sustainable choice.