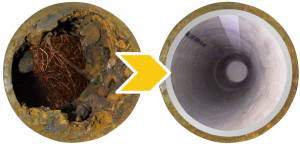

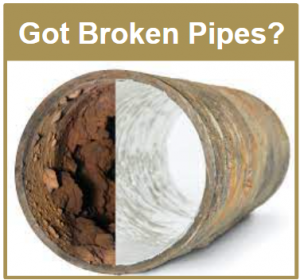

Miami Trenchless Pipe Repair Fixes Broken Pipes Underground For 50 Years

—

For a 2,000 sq. ft. house in Miami:

Trenchless Epoxy Pipe Lining

-

- Takes 4 days

- Costs $17,000

- Has a 50-year warranty!

- Stay in home

Pipe Excavation & Replacement

-

- Takes 4-8 weeks

- Costs $50,000 – $75,000

- Tile, Terrazzo, Marble, Wood replacement

- Kitchen and bathroom cabinets replacement

- Must vacate home

“Epoxy Pipe Lining” Repairs Underground Pipes Without Digging, Costing 60% Less!

Our Pipe Lining Has A 50-Year Warranty!